ASCEND ELECTRONICS® LABORATORY POWER SUPPLY

Laboratory Power Supplies (LPS) and multimeters, oscilloscopes, and power loads are essential tools for laboratories, development and research centers, manufacturing, test departments, chemical processing, hobbyists, and many more.

A DC (Direct Current) laboratory power supply is an electrical device that powers an electrical DC load. Ascend Electronics® designs, manufactures, and supplies highly reliable and intelligent power supplies for industrial and commercial applications.

For most users, the purpose of owning and using a DC Laboratory Power Supply is to convert the AC supply from the 110V / 220V wall power plug to a defined DC voltage for their application. DC laboratory power supplies are also called benchtop or desktop power supplies. Ascend Electronics offers a variety of desktop power supplies to meet the diverse needs of our customers. These instruments fall into two main categories, linear and switch-mode power supplies.

All our desktop power supplies convince by their high accuracy. Well-designed displays provide a complete view of the parameters and output waveforms. In addition, voltage and current controls and adjustable over- and under-voltage and current limitations are implemented in the supplies.

CLICK TO SEE LAB BENCH DIGITAL DC POWER SUPPLY

CLICK TO GO TO LAB BENCH LINEAR DC POWER SUPPLY

Some features of our LPS:

• Linear and Switching Lab Power Supplies

• Power levels up to 3000 Watt on Bench Top Models

• Voltage Ranges for 0V to 12kV

• Current Ranges from 0 to 3000A

• Single to multi-power adjustable and monitored outputs

• High accuracy, high resolution, and high precision bench power supplies

• Overload, over-voltage, -current, -temperature and reverse polarity protection

• CV (Constant Voltage) and CC (Constant Current) operations, auto CV and CC switch

• TFT color or mono LCD and LED displays

• High-speed rotary dial and keypad input

• Built-in beeper alarm

• Panel lock and output ON/OFF function

• List mode function, 100 sets save & recall for voltage, current and time setups, easy use in autotest

• Remote sense function

• Low resistance measurement function, display load resistance value

• Battery charge mode

• USB device for data storage and recall from PC

• Standard RS232 interface, support SCPI commands, support Labview

• Standard 0-5V analog control

• Optional RS485 interface, support ModBus

• Optional RS232-to-USB cable

• Including Test Accessories

Read More about our Oscilloscope

Description of operation linear power supply

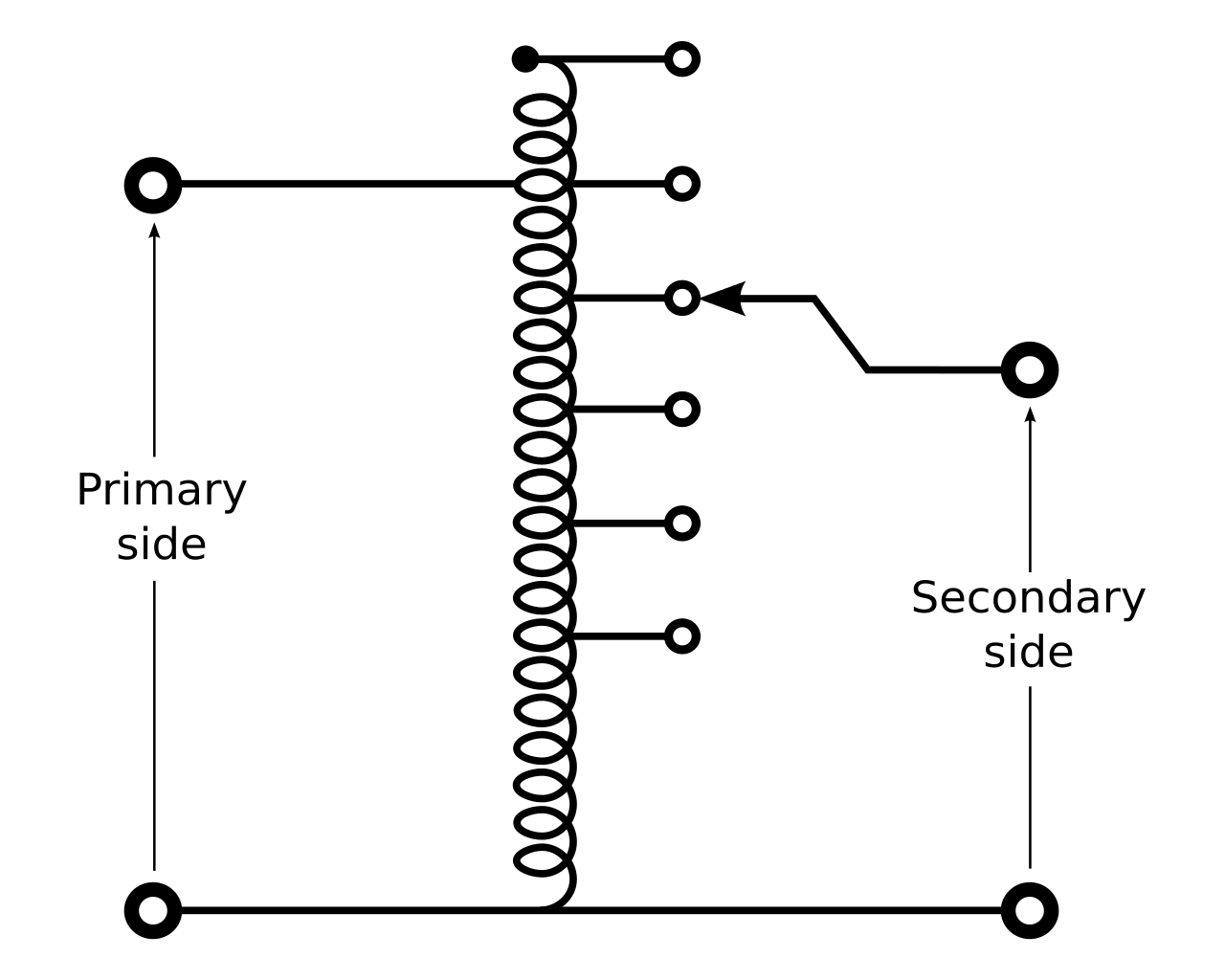

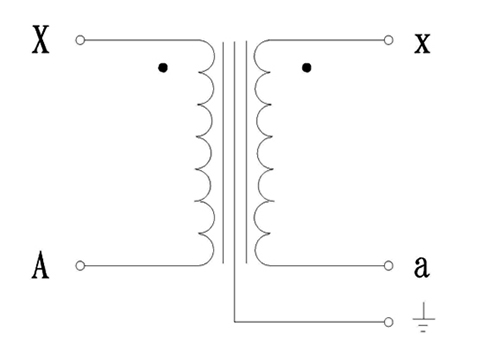

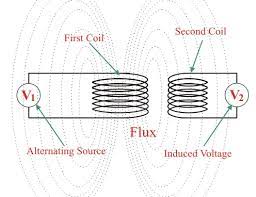

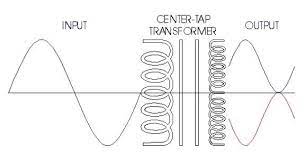

In linear power supplies, a rectifier circuit converts the output voltage from a step-up or step-down transformer to the desired DC output voltage. After the rectified DC voltage is passed through a filter, the power passes to the adjustable linear regulator, which provides the exact user-preset DC voltage and current to the output.

Description of operation switching mode power supply

In a DC switch-mode power supply, input filtering ensures immunity to mains-borne noise and, at the same time, reduces emission back into the mains supply, which is a greater concern with switch-mode power supplies than with their linear counterparts. In addition, power factor correction is applied to the rectified filtered AC line voltage to reduce power losses and current harmonics that can cause interference with other appliances connected to the same network.

High-frequency switches the DC voltage to a much higher voltage than the AC input line, allowing it to be converted to another voltage via a smaller, lighter high-frequency transformer. The transformed voltage is again rectified and filtered before being connected to the output. Switching is controlled by the SMPS controller, which typically generates a PWM signal and receives feedback from the power supply output.

Linear vs. switch-mode DC power supply

Each power supply operation type has its own advantages and disadvantages.

The high frequency (HF) used in SMPS results in a much smaller and lighter transformer design used to increase or decrease the voltage that would be required at a 50/60 Hz (Herz) power frequency, resulting in a 20% to 80% smaller and lighter power supply construction than a corresponding linear power supply. Although, high-frequency generates noise that can interfere with sensitive electronic equipment.

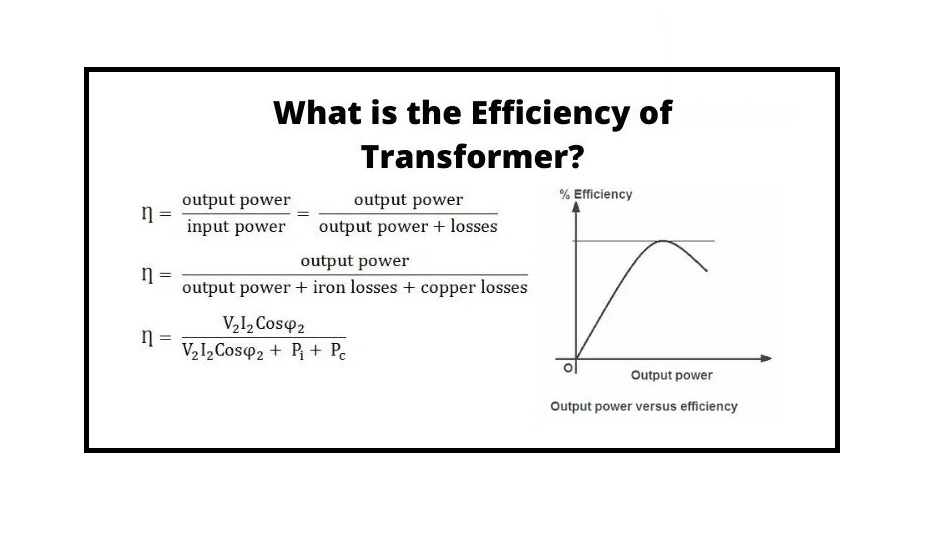

Let's bust, at this point, a common myth. Many web pages state these smaller high-frequency transformers are also considerably more power efficient than 60Hz line transformers. That is not a correct statement.

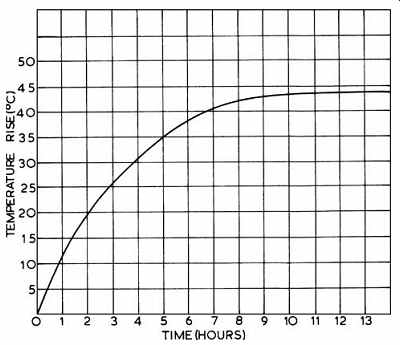

The energy efficiency of a transformer depends on the design, the construction, and the frequency-dependent materials used. For example, Ascend Electronics® manufactures line transformations (50/60 Hz) with an energy efficiency of up to 99%, which is only possible due to the low frequency. In contrast, high-frequency transformers must cope with additional energy losses caused by increased frequencies, such as higher eddy currents, skin effects, proximity effects, and other frequency-sensitive core material performance.

The low-frequency line transformer's energy spectrum has pretty much only one component at 50 respective 60 Hz (for a clean resistor load not rectified). While HF transformers receive rapidly modulated pulses, they must operate in a large energy spectrum, the harmonics of such square pulses. All those add up to the HF-Transformer losses and reduce energy efficiency. However, since the transformer size gets smaller with increasing frequency for a given constant power, the power density gets bigger (increase in watts per cm3).

With an increasing load power, the power efficiency of the switch-mode power supply (SMPS) increases to a certain maximum. If the load power keeps rising, the power efficiency will reduce again. The SMPS efficiency can be below 50% for a low power load, whereas at the nominal load, the efficiency can max out to 85% or more.

What is the SMPS energy efficiency compared to a linear adjustable power supply? Both laboratory supplies can regulate a larger output voltage, for example, 0 V to 30 V, with a current of 10 Amperes over the entire voltage range. Assuming that the SMPS has a constant power efficiency of 85%, regulating its output power directly from the 110V main, the linear power supply, on the other hand, regulates the output voltage from a constant DC voltage of 33V supplied by the transformer. In a first-thought experiment, both instruments regulate an output voltage of 1V. The linear load is set to require 10 amps from the supply, which corresponds to a load power of 10 watts. The efficiency of SMPS at this voltage setting is, by definition 85%, so the power dissipation is 1.5 watts (15% * 10 W).

On the other hand, the linear regulator has to burn 32 V to provide 1 volt, which corresponds to a power loss of 320 watts (32 V * 10A), heat that the regulator dissipates. The transformer must deliver 330 watts. Therefore, the efficiency of the linear regulator is only 3% (10 W / 330 W).

In a second experiment, we adjust the output voltage to 30V at 10 amps. The output load now takes up 300 watts. The SMPS efficiency is still 85%, so the SMPS converts 45 Watts (15% * 300 W) into heat. The linear regulator only burns 30 watts (3V * 10A) and now has an energy efficiency of 91% (300W / 330W) and outperforms the SMPS. In this example, we have neglected the power dissipation of the linear power supply's rectifier circuit, capacitors, and transformers. The experiment is to demonstrate that the efficiency of linear power supplies mainly depends on the voltage drop VDrop of the regulator and is proportional to VOut / (VOut + VDrop). Note that in the last few years, the technology for linear regulation has drastically improved, reducing the loss of diodes and regulators. Today low drop-out voltage regulators with drop-out voltages of 0.5 Volt became very common. Note that very low output noise SMPS has a second output state that consists of low drop-out regulators to suppress the switching noise ripples from reaching the load.

Some other pros and cons exist between the different power supply technology. But, again, those have to be considered in much broader content when selecting one or the other type since technology and design concepts can overcome some of the cons.

• Switch-mode power supply generates high-frequency noise that can interfere with sensitive electronic equipment.

• Linear power supply requires larger semiconductor devices to regulate the output voltage, generating more heat, resulting in lower energy efficiency.

• A linear power supply with adjustable output power over a voltage range from 0V to 30V operates on average with 60% to 70% efficiency for a 24V output voltage. In contrast, a switch-mode power supply operates near 80% or more.

• Linear power supplies have transient response times up to 100 times faster than their switch-mode counterparts, which is essential in certain specialized areas.

• In general, a switch-mode power supply is best suited for portable equipment since it is lighter and more compact.

• Because the electrical noise is lower and easier to contain, a linear power supply is better suited for powering sensitive analog circuity.

Pros and cons of linear power supplies compared to switch mode power supplies

PRO

• Simpler and more robust

• Easier to design and maintain

• Low noise – suited to noise-sensitive applications

• Faster transient response times – therefore, may be better suited to more dynamic loads

CON

• Larger and heavier

• Less efficient if regulated over a larger voltage range

Pros and cons of Switch Mode Power Supplies (SMPS) compared to linear power supplies

PRO

• Typically much smaller and lighter

• On average, more efficient than regulated linear power supplies, when regulated over a larger voltage range

• lower cost due to much smaller transformers used

CON

• More complex

• Can be a potential source of EMI (electromagnetic interference) and RFI (radio-frequency interference)

• Slower transient response times